Glass condensers as glass container,glass heat interchanger,glass heat exchangers,Shell & Tube heat exchangers

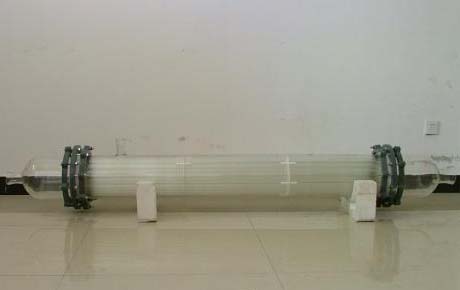

Glass Shell and Tube Heat Exchangers are of recent development. These heat exchangers can be used for condensation of vapours, vaporization, cooling and heating of liquids. The shell and tube heat exchangers are available in various combinations of Glass/Metal/FRP in shell or headers. Glass shells are constructed using standard glass components like Pipe section, Tee, Cross etc. Metal shells are generally constructed of MS in one piece.

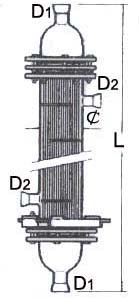

Shell and tube heat exchanger consists of a cylindrical shell which houses a glass tube bundle. Tubes are sealed with shell with the help of PTFE tube sheets. Each tube is individually sealed by Viton 'O' ring in tube sheets at both the ends. Baffles are provided in the shell to maintain state of turbulence of fluid as well as to hold the tubes.

Salient Features :

1.Universal corrosion resistance an excellent alternative to expensive MOCs like graphite, hastelloy, copper titanium, tantalum and other exotic metals.

2. Excellent heat transfer as fouling does not occur on smooth glass surfaces.

3. Flexibility of installation vertical/horizontal.

4. Easy replacement of tubes for repair and cleaning.

5. Available in wide range of HTAs.

6. Ease of installation due to light weight.

7. Economical.

8. Suitable for applications where large HTAs are required in limited space.

Advantages Over Conventional Coil Type Heat Exchangers :

1. The overall heat transfer coefficient in shell and tube heat exchanger is about 3 times higher than in coil type heat exchanger.

2. The pressure drop in shell and tube heat exchanger is minimal compared to 2-3 kg/cm2 in coil side of coil type heat exchanger.

3. Stuffing box sealing allows easy tube replacement.

Shell and tube heat exchangers are of recent development .

Shell and tube heat exchanger can be operated within a temperature range of -40℃ to 200℃ on either side. However, differential temperature should not exceed 120℃ at any point. All the Shell and tube heat exchangers can be used predominantly under full vacuum, provided differential pressure does not exceed 0.3Mpa.

It is generally used for horizontal installation.but also they can be installed vertically.PTFE per forated plates supports the glass tubes .shell and tube exchangers are used for surface area . more details and dimensions can be sipplied on request.

Varieties specifications:

|

Area (m2) |

Diameter |

Tubules' Quantity |

L mm |

D1 mm |

D2 mm |

|

3 |

φ180 |

55 |

2100 |

40 |

25 |

|

50 |

25 |

|

80 |

25 |

|

5 |

φ230 |

85 |

2400 |

50 |

40 |

|

80 |

40 |

|

100 |

40 |

|

10 |

φ300 |

151 |

2700 |

40 |

50 |

|

50 |

50 |

|

80 |

50 |

|

100 |

50 |

|

125 |

50 |

|

150 |

50 |

|

15 |

φ300 |

151 |

3650 |

40 |

50 |

|

50 |

50 |

|

80 |

50 |

|

100 |

50 |

|

125 |

50 |

|

150 |

50 |

GLASS Shell And Tube Heat Exchanger PDF DOWNLOAD: 1 2